Sealers are available for 4 oz. 2-piece Draw Redraw DRD Steel Aluminum Cans A streamlined process yields multiple benefits.

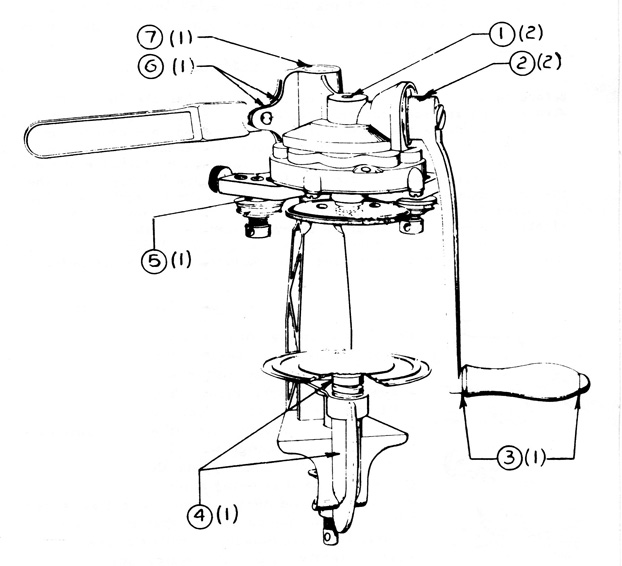

The bolt assembly kit includes the following.

. Available by SPECIAL ORDER please allow extra time for delivery. Crafted of the finest hand cast aluminum. PAC manufactures one of the most extensive lines of industrial vacuum packaging machines in the industry.

The process of attaching the can end lid to the can body is called double seaming. Cans through 105 oz. Can sealer hermetically seales cans.

Sealers Maximum Series case erectors consistently outperform their competition. The biggest drawback when rolling sealer on brick pavers is that the roller can pick up the joint sand and roll it over the top of the brick paver surface. A rotating base supports the can during sealing while two sets of rollers lock the lid to the can and then tighten and smooth the seam.

We highly suggest using a surge protector. A two dimensional drawing depicting the exact specifications if a tin in its pre-fabricated flat state used for setting artwork up to fit the can. Two-piece steel and aluminum cans have only one seam around the top end double seam.

Fewer steps and moving parts mean fewer things to go wrong. Vertrod drop sealers are ideal for speeding up smaller production runs particularly in applications that require the removal of air in the bag prior to sealing. And no one simplifies case erecting like AB.

These drop sealers function optimally when paired with a bag opening device. To properly seal a can. Identify the correct replacement seal.

For architecturally exposed steel that is to be painted seal welds may be specified to prevent unsight- ly rust bleeding. Plug the band sealer into a standard 120 Volt 60Hz wall outlet or surge protector. Manual and electric can sealers are available for sealing the open top cans.

If you are unable to identify the seal it will be necessary for you to measure the old seal for correct identification. The seals are arranged by shaft size from smallest to largest. Remove bolts from underside of wooden shipping board that sealer is attached to.

Lathe tail-stock diesel engine fuel pump carburettor etc. While roller applying a sealer is easier than spraying roller application does not work as well on pavers compared to something concrete. Refer to page 2 through 6 to identify the seal.

Case Sealer seals both top and bottom with pressure sensitive tape and a cost effective price. Examples of such drawings are. Hand powered sealers must be firmly clamped or bolted to a sturdy table or bench clamp included.

You can measure according to the Drawing Codes for the correct. - 16528809 daisyhortelano11 daisyhortelano11 4 days ago Filipino Senior High School answered 18. The inboard or primary seal keeps the product contained within the pump housing.

Open Top Can Sealers. Coverclosure option in which a pliable ring fits to the interior of a tin allowing for a straight-sided slender profile can. Reubuhhit to be a good day for you and the family have been trying to reach.

2 bolts - 516 2 rubber washers 2 flat brass washers 2 hex-head thin brass jam nuts C7715-5. Heat sealer - foot sealer available at ImpulseSealerSupply. Height adjustment can be made with by moving the Adjustable Base Arm D212 up or down on the Wall Hook D211 for 254 or 32 oz cans.

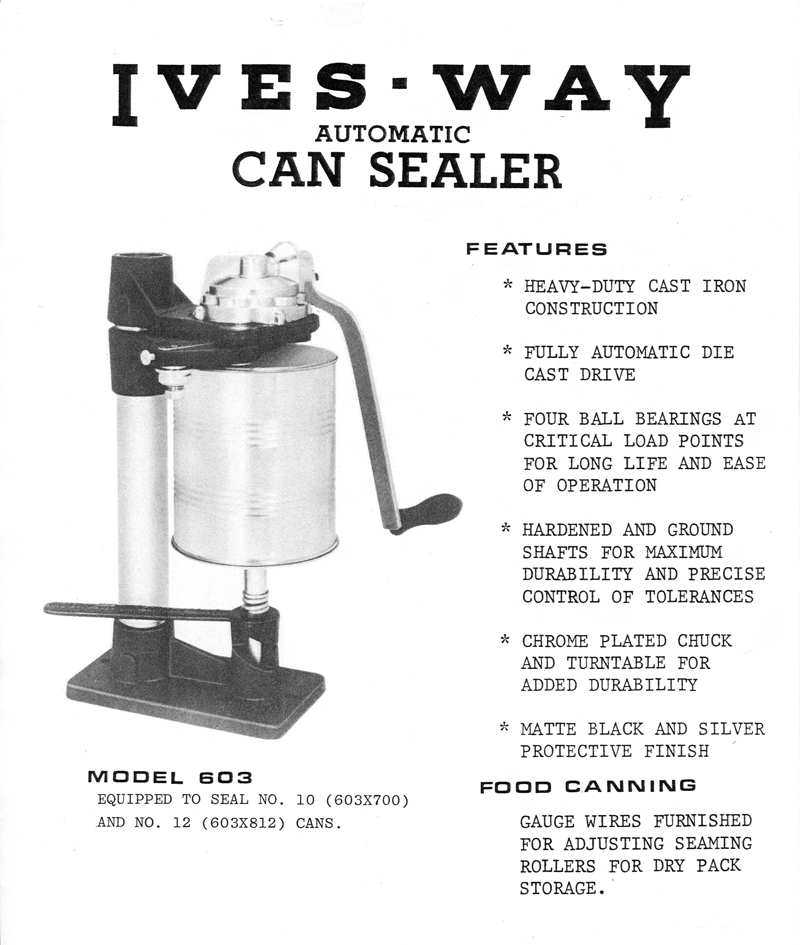

BSB Kit - C7715-1 Ceramic tank Seal - C7715-2 FillValve Air Tube - C7715-3 Tank to Bowl Gasket C7715-4 C7715-7 Flush Valve N7714TL Toilet Lid. While many of the same reasons for employing a surface finish apply to both 3D-printed parts and parts produced with more traditional methods you should always consider the unique features of your part when choosing surface finishing processes to use. This heavy duty manually operated can sealer is factory equipped to seal 10 cans 603x700.

Hand-operated can sealers are designed for continuous use and operate by using a hand crank or flywheel to press the lid down on the can. Safety rules and take necessary precautions can result in serious injury as well as damage to equipment. Examples are Dura RO and Crane double 811T.

Comes equipped to seal 8oz 12oz. This seam is formed by mechanically interlocking the outside end of the lid known as the curl with the top part of the can body known as the flange. 150 cans per hour.

Recent testing has shown that double seal life is virtually unaffected by process upset conditions during pump operation. Vacuum sealers are used primarily for shelf life extension volume reduction and corrosion protection. This sealer is ideal for businesses that require the efficiency of a heavy duty sealer and a relatively inexpensive way to seal these large size cans.

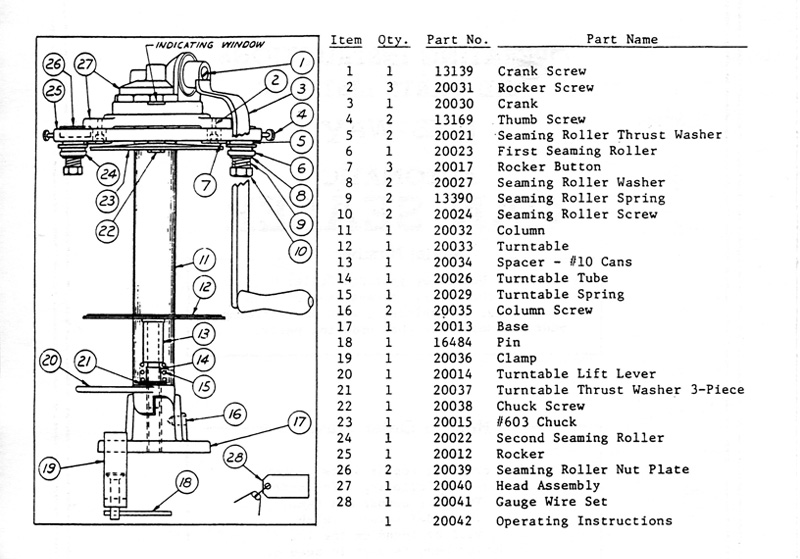

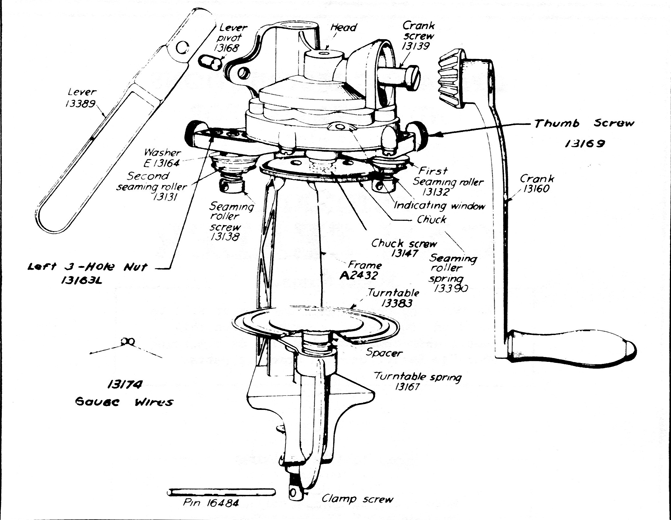

The metal inner seal parts are never exposed to the liquid product being pumped. ASSEMBLY DRAWING SPARE PARTS. 1234 Installation Assembly Drawing On this drawing the location and dimensions of few important parts.

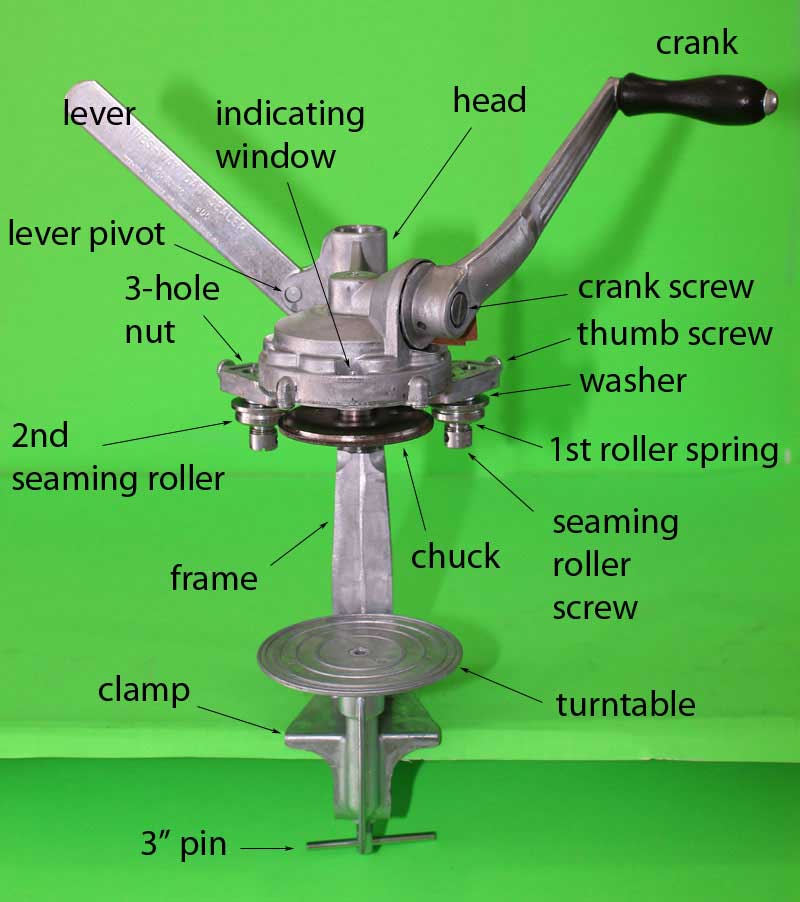

Equipped with a fly wheel for easier operation. Run an empty can in the machine to seal the First Operation. Draw the Can Sealer and label its parts.

The outboard or secondary seal prevents the flush liquid from leaking into the atmosphere. Beverage cans B64 lid. EL-DD comes with rubber feet that can be installed on the bottom unthreaded holes next to.

These are just a few of the ways surface finishing can be useful. No skill or experience is required to perfectly seal tin cans automatically. Seal welds may be specified on parts to be galvanized to prohibit pickling acids andor liquid zinc from entering into a specific region.

Drawing is an assembly drawing of a group of related parts that form a part in a more complicated machine. Vacuum sealers work by removing the air in a bag prior to sealing. They can be tapered to make them nestable yielding reduced shipping costs to customers in distant locations.

Flywheel can sealer. Fast and easy case. SF202A Master Flywheel Can Sealer 8oz 12oz 16oz Beverage Cans 94900.

Handy-Dandy Hand-Held Heat Sealers If your business has low volume packaging and sells products in small bags then hand held sealers are right for you. A double mechanical seal consists of two seals arranged in a series. The groove marked 1st should slide over seam on can.

Remove the can and slip the Gauge over the seam. Never operate or service your band sealer until you have read this manual completely and understand it fully. These open top can sealers can be used on several sized cans and are made for heavy-duty applications.

Double mechanical seals are offered in two arrangements. Viscous abrasive or thermosetting fluids are easily sealed without a need for expensive metallurgy. Additional chucksspacers may be purchased.

Hand held sealers are a smaller version of constant heat sealers and therefore can seal materials such as foil Mylar and polycellophane which have higher melting. Draw the Can Sealer and label its parts. The seam will not fill the entire length of the groove but the Gauge should slip on far enough so that it.

1 See answer jolliefe jolliefe Answer.

Uk Engineer Purchased Cans Sealing Machine For Beer Container Easy Open Can Sealer Equipment Shenzhen Penglai Industrial Corporation Limited

0 comments

Post a Comment